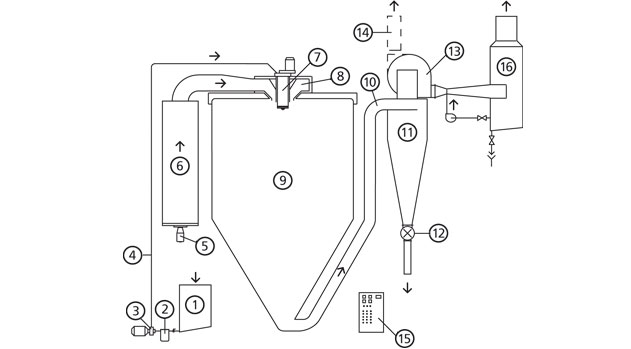

Spray Drying Process

The Spray drying is the process of spraying a solution or suspension in a hot air flow that dehydrates them almost instantaneously. Said process is advantageous in relation to other types of drying.

Spray Drying Process Description.

The liquid product is located inside the Feed Tank (1). Through a Product Filter (2), the liquid is propelled through the Pump (3) and the Piping set and accessories (4) up to the Sprayer (7). The Burner (5) and its Chamber (6) provide the necessary temperature for the hot air flow, that forced by the Fan (13), circulates through the Disperser (8) spreads uniformly round the Atomizer disc 7), and where the sprayed liquid comes out. When this meets hot air, drying occurs almost at once due to the dimension of the drop. Since part of it is solid, then falls in the form of dust inside the Drying Chamber (9), and is aspired by the Fan (13), taken to the Interconnecting Piping (10) up to the Cyclone (11) which will be the responsible of separating the dust from air and extract it as final product. Said final product comes out through a Rotating Valve (12) for packaging. The separated air will escape through a Chimney (14) taking away a small percentage of dust with it. To recover the loss, GLX offers as an optional, the use of a Gas Washing System (16) that allows the recovery of the product and reuse to avoid loss and also to prevent contamination from happening.

Spray Dryer Components

1) Feed Tank.

2) Product Filter.

3) Dosing Pump.

4) Piping Set,

Valves and Accessories.

5) Complete Burner.

6) Direct Hot Gases

Generator.

7) Complete Atomizer.

8) Hot Air Disperser.

9) Drying Chamber

with Doors and Sight Glass.

10) Interconnection Conduits.

11) Product Outlet Cyclone.

12) Rotating Valve.

13) Aspiration Fan.

14) Chimney.

15) Control Panel.

16) Effluent Gas Scrubber.